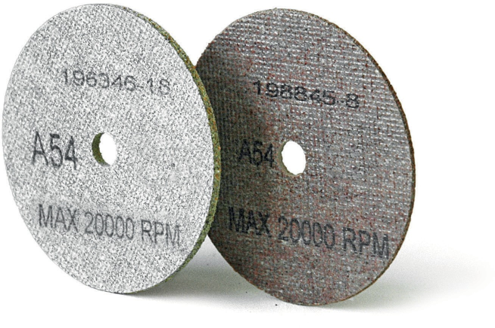

Our Industrial finishing Abrasives products will help you to get high-quality mirror-finishing. Our finishing abrasives products are made by an exclusive manufacturing process to give full reliability in terms of quality, performance and safety. See all Fen Abrasivi Finishing abrasives tools for various applications here.

Please contact us and one of our sales staff will be glad to help you.