LOCKING ACTION

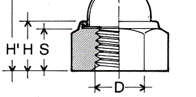

The locking effect is guaranteed by the spring action, which presses the nut collar on the screw; this device does not reduce the efficiency even after several assemblies, as the locking element has no direct contact with the friction surfaces.

APPLICATIONS

VARGAL can be used without applied tightening torque, due to the locking action which maintains the locknuts in the desired position, avoiding the loss of the assembly parts.

RESISTANCE TO VIBRATIONS

An excellent resistance to vibrations is guaranteed, as the vibrations increase the contraction of the spring on the collar with the consequential rise in the

force applied by the same collar on the screw thread.

TEMPERATURES VARIABILITY PROOF

VARGAL 10 locknuts are supplied with stainless steel spring.

They can operate on temperature range between – 50 °C up to + 200 °C.

The maximum endurable temperatures depend on specific application and are conditioned by several factors such as ventilation, heat sources.

For applications different than the ones above mentioned, we suggest tests under real operating condition.

EASY INSTALLATION

No special tools are required for the fitting of VARGAL 10 locknuts.